Lediant has a strict control on the quality of led downlight products. Under ISO9001, Lediant Lighting firmly sticks to the testing and quality inspection procedure to deliver quality products. Every batch of big goods in Lediant execute inspection on finished product such as packing, appearance, performance, dimming & photoelectric parameters etc to ensure they conform to requirement. We choose sampling test from the bulk goods, which being packed on the production line by a certain percentage (GB2828 Standard).We are confident to offer 3 and 5 years warranty on our products.

Today let me introduce the inspection of power cord for you.

For the power cord, Lediant checked it more than 3 times.

First of all, when the material enters our factory, we will do a hand inspection.

Secondly, daily inspection is performed during the production process.

Finally, after the downlights are finished, we will also carry out corresponding sampling inspection.

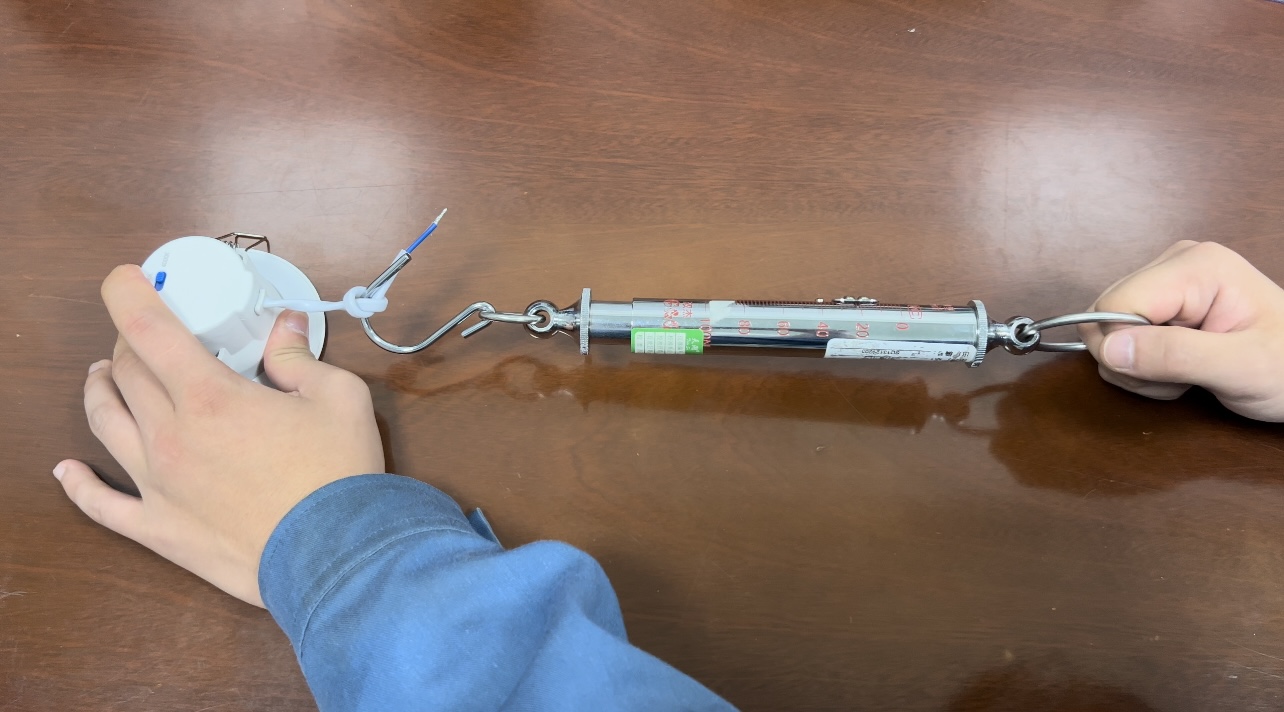

Generally speaking, different downlights, according to the requirements of different customers, we will carry out different times of cord anchorage test. The cord anchorage test is to check the retentivity of the power cord.

Lediant’s standard: The power flexible wire must be equipped with a pressing device to prevent the flexible wire from being pulled out. Pull 25 times,the displacement of it will not exceed 2mm.

Internal Wire:

The current is equal to or greater than 2A, the minimum nominal area is 0.5mm². Current is equal to or less than 2A, the minimum nominal area is 0.4mm².

Internal wires shall not be scratched by sharp edges.Sharp edges and internal connections need to be protected by insulating bushing.

The internal line extending 80mm out of the lamp shall be assessed according to the external line.

Post time: Oct-26-2022